Cymat Technologies Ltd, headquartered in Toronto, Canada, stands at the forefront of innovation with exclusive rights in producing Stabilized Aluminum Foam (SAF), marketed under the trade name Alusion™. This groundbreaking material is revolutionizing lightweight aluminum panels, offering unparalleled versatility and myriad architectural applications.

Versatility and Unique Properties of Alusion™

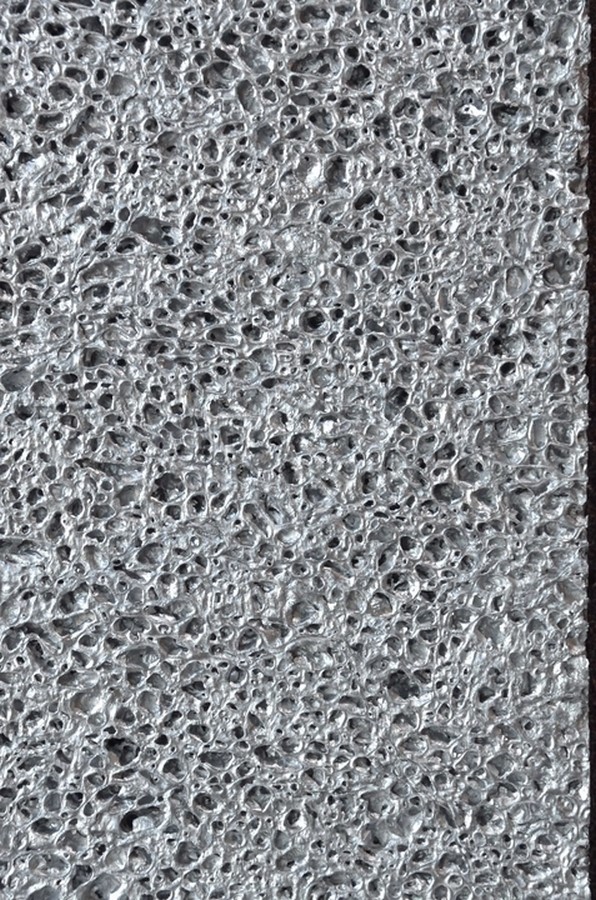

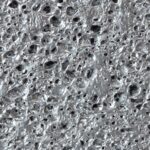

Alusion™ Stabilized Aluminum Foam presents a remarkable combination of aesthetics and functionality. Its distinctive appearance coupled with sound-absorbing properties makes it an ideal choice for architectural projects requiring both visual appeal and acoustic performance. The foam panels, resembling a metallic sponge, boast strength and lightness, offering a modern and dramatic visual impact.

Diverse Specifications and Customization Options

For architectural purposes, Alusion™ foam panels are available in thicknesses of 12.7mm, 25.4mm, and 43.2mm (1/2”, 1”, & 1.7”) and three densities (Large Cell, Mid Cell, & Small Cell), with custom options also provided. Each thickness and density category comes with its own stress/strain curve, ensuring suitability for various structural requirements.

Exceptional Material Properties

Alusion™ Stabilized Aluminum Foam shares the buoyancy, flame resistance, and corrosion resistance of conventional aluminum. Its surface can be maintained in its solid form or undergo surface treatments to achieve diverse appearances, from a solid shimmering finish to a translucent water froth look. Moreover, the material is 100% recyclable, aligning with sustainable architectural practices.

Superior Manufacturing Process and Advantages

Cymat Technologies Ltd employs a proprietary continuous panel production process, giving Alusion™ a competitive edge. This process enables the production of aluminum foam in dimensions and volumes unmatched by competitors, with consistent quality and a uniform yet random aesthetic. The lightweight nature of the material facilitates easy installation, further enhancing its appeal for architectural applications.

Comprehensive Features and Surface Solutions

Alusion™ foam panels offer a host of features, including:

- Modern and dramatic appearance

- 100% recyclability with 20% recycled content

- Acoustic absorption properties

- Non-combustibility with a flame spread rating of zero

- High corrosion resistance

- Strength, durability, and resilience of aluminum

- Windload testing exceeding 220 miles per hour (354 km/hr)

Moreover, a range of surface solutions such as resin coating, water jet cutting, specialized powder coatings, and wet paints enhance the material’s resistance to salt and chemicals, expanding its utility in various environments.

Application and Use in Construction

Alusion™ foam panels find wide application in construction, including facades, ceilings, and exterior/ outdoor structures. Available in slabs, plates, and panels, the material offers versatility in design and construction while contributing to sustainable practices through its use of recycled materials.

Conclusion

In summary, Alusion™ Stabilized Aluminum Foam represents a paradigm shift in architectural materials, offering a blend of aesthetics, functionality, and sustainability. With its diverse specifications, superior properties, and customizable options, it stands as a testament to Cymat Technologies Ltd’s commitment to innovation and excellence in the field of materials technology.